The Development of In-Mold Decorations in Production Processes

The Development of In-Mold Decorations in Production Processes

Blog Article

Grasping In-Mold Decorations: Strategies, Patterns, and Best Practices for Optimal Outcomes

In the realm of manufacturing, the art of in-mold decorations stands as a pivotal facet of item design and manufacturing. As markets continuously look for innovative ways to improve visual appeal and capability, mastering the complexities of in-mold decorations has actually arised as a critical capability. From choosing the appropriate products to including advanced layout trends, the journey in the direction of attaining optimum lead to this domain name is diverse. By delving into the techniques, patterns, and best techniques that underpin successful in-mold decoration processes, organizations can open a world of possibilities that not only boost the visual allure of their products however also improve production effectiveness and bolster customer involvement.

Product Selection

Product selection is an important facet of understanding in-mold designs, as it straight influences the high quality and toughness of the end product. When choosing materials for in-mold decors, it is vital to consider elements such as compatibility with the molding procedure, the desired visual result, and the ecological conditions the item will certainly face. Polycarbonate materials like polycarbonate, polypropylene, and abs are frequently utilized for in-mold designs as a result of their convenience and capability to achieve complex styles. These materials supply excellent moldability, making it possible for suppliers to create complex shapes and patterns with accuracy.

Additionally, products with high heat resistance are favored for in-mold decorations, specifically for products that will be subjected to raised temperatures throughout their lifecycle. By meticulously choosing the ideal material for in-mold decorations, makers can boost the general high quality and resilience of their items, fulfilling the assumptions of both clients and end-users - In-Mold Decorations.

Layout Technology

An important aspect in advancing the area of in-mold designs is the continual expedition and execution of style advancement methods. Layout development plays a crucial function in enhancing the aesthetic charm, capability, and total quality of products produced utilizing in-mold decoration procedures. By incorporating ingenious design elements, producers can separate their items on the market, draw in customers, and stay ahead of rivals.

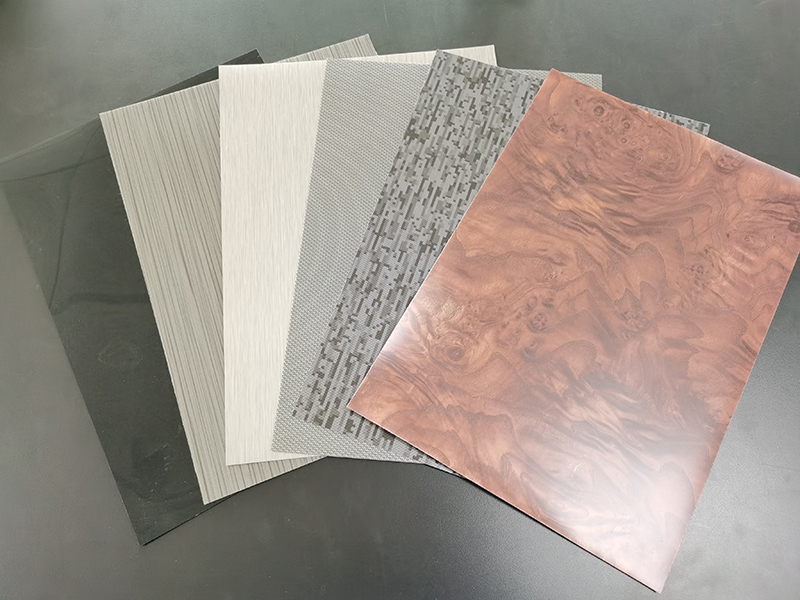

One of the crucial elements of design innovation in in-mold decorations is the assimilation of detailed patterns, appearances, and graphics that were previously testing to achieve with conventional decor techniques. Advanced technologies such as 3D printing and digital layout tools allow developers to produce complicated and thorough styles that can be seamlessly transferred onto molded parts. Additionally, the usage of vibrant colors, metal coatings, and special impacts like gloss or matte structures can further elevate the aesthetic charm of in-mold decorated products.

Moreover, design technology prolongs past visual appeals to incorporate practical enhancements such as ergonomic shapes, incorporated attributes, and adjustable aspects that provide to certain customer needs. By accepting design development, suppliers can open brand-new opportunities for creative thinking, product, and personalization distinction in the affordable landscape of in-mold decors.

Production Performance

Reliable production procedures are vital for equating the innovative designs developed in the field of in-mold decors right into high-grade finished products that fulfill market needs and consumer assumptions. In the world of in-mold decorations, production effectiveness encompasses various crucial elements that contribute to the total success of the manufacturing procedure. One essential element is the optimization of mold and mildew style and tooling to guarantee precise and smooth design transfer onto the end product. By fine-tuning mold and mildew setups and buying high-grade tooling materials, producers can enhance effectiveness and consistency in production.

Automation not only increases the production procedure but additionally boosts accuracy and repeatability, leading to a much more high-quality and consistent end product. On the whole, an all natural method to manufacturing effectiveness is vital in making best use of the potential of in-mold decor methods and attaining optimum results in the affordable market landscape.

Quality Assurance Steps

What are the vital methods for making certain stringent quality assurance actions in the realm of in-mold designs? Quality assurance measures are critical in in-mold decor processes to make certain the manufacturing of flawless and top notch completed products. One vital method is the application of extensive assessment protocols at every phase of the production process. This entails conducting detailed visual assessments, dimensional checks, and shade uniformity assessments to identify any inconsistencies or issues early.

Making use of advanced modern technologies such as automatic examination systems can additionally improve the quality control procedure by providing precise and trustworthy data for evaluation. have a peek at this website These systems can find blemishes that may be missed out on by hands-on inspections, therefore enhancing total product top quality and consistency.

Routine training and development programs for workers associated with the in-mold decoration process can also contribute to maintaining top notch criteria. By educating personnel on finest techniques, high quality expectations, and the value of attention to detail, firms can foster a society of high quality awareness throughout the company.

Customer Appeal

To boost the bankability of in-mold decoration items, catering and understanding to customer preferences play an essential duty in identifying their appeal and success. Consumer allure in in-mold decorations is influenced by different aspects, consisting of design aesthetics, color options, longevity, and general performance. Customers are progressively seeking personalized and distinct products that reflect their originality and design. For that reason, offering personalization alternatives such as personalized layouts, color variants, and textural elements can substantially improve the allure of in-mold decoration products.

Verdict

In-mold decors supply a functional and reliable method to improve item visual appeals. By very carefully choosing materials, accepting innovative designs, enhancing manufacturing procedures, applying quality assurance steps, and prioritizing consumer allure, manufacturers can achieve optimum outcomes. It is critical for companies to continually adjust and enhance their approaches to stay competitive out there. In-Mold Decorations. Mastering in-mold designs requires an all natural method that considers all facets of the production process to make sure success.

In the world of production, the art of in-mold designs stands as a crucial aspect of product design and manufacturing. Style development plays a critical duty in enhancing the aesthetic appeal, functionality, and total high quality of items produced using in-mold decoration processes.One of the key aspects of style innovation in in-mold decorations is the assimilation of detailed patterns, structures, and graphics that were previously challenging to accomplish with traditional design techniques.Reliable manufacturing procedures are essential for converting the cutting-edge layouts created in the area of in-mold decors into top notch ended up items that satisfy market needs and consumer expectations. Supplying personalization options such as customized designs, shade variants, and textural aspects can substantially enhance the appeal of in-mold design items.

Report this page